+8801600371198

sign_bd@yahoo.com

Account Login

Home>>Compliance Safety Sign>>Spinning safety signs

Spinning Safety Signs

The Crucial Role of Safety Signs in the Spinning Industry

Understanding the Importance of Spinning Safety Signs

Safety is a cornerstone of every aspect of the spinning industry, from yarn transformation to the intricate processes involved. Safety signs play a critical role in maintaining a secure environment for workers. This article explores the significance of safety signs in the spinning industry and their role in risk assessment.

Risk Assessment in the Spinning Industry

A comprehensive risk assessment identifies health concerns and fire safety issues across various sectors of a spinning mill, including the ring section, simplex section, winding section, blow room section, drawing section, comber section, carding section, and cotton godown section. These signs are essential visual cues that promote a culture of safety within the textile industry.

Purpose of Spinning Safety Signs

Safety signs are more than decorative elements in the spinning industry; they serve as silent, effective guardians for workers engaged in various processes. These signs ensure that everyone involved in production remains safe by providing critical information on safe practices and emergency procedures.

Detailed Risk Assessments Across Spinning Mill Sections

Ring Section Risk Assessment

In the ring section, where cotton is spun into yarn, accuracy and speed are crucial. Safety signs here advise workers on the safe use of equipment, accident prevention, the use of masks and earplugs, and emergency fire procedures.

Simplex Section Risk Assessment

The simplex section focuses on yarn winding and machine operation. Safety signs emphasize regular equipment maintenance and safe operational methods to protect workers.

Winding Section Risk Assessment

As the final yarn is developed, safety signs guide workers on safe yarn handling and proper organizing procedures.

4. Comber Division Risk Assessment

Cotton fibers are cut for further processing in the comber section. Safety signs advise workers on how to use the comber machine safely, reducing the chance of accidents.

Carding Section Risk Assessment

During the carding phase, knotted cotton strings are straightened. Safety signs warn employees to use carding equipment properly to ensure their safety.

Blow Room Section Risk Assessment

Raw cotton is cleaned and processed in the blow room. Precautionary signs instruct workers on handling respiratory issues and ensuring proper safety practices.

7. Risk assessment for Drawing Section

Cotton fibers are further aligned before spinning throughout the drawing process. Here, safety signs highlight the importance of machinery equipment and safety gear.

Drawing Section Risk Assessment

Cotton fibers are aligned before spinning in the drawing section. Safety signs highlight the importance of using machinery correctly and wearing appropriate safety gear.

Cotton Godown Section Risk Assessment

Safety signs in cotton warehouses emphasize proper stacking and handling to prevent accidents and fires.

Ensuring Fire Safety in Textile Production

Fire safety is a critical concern in the spinning industry due to the transport of volatile substances. Fire safety signs act as the first line of defense against potential disasters, providing information on fire incidents, emergency fire safety regulations, and the locations of fire extinguishers and assembly points.

The Role of Fire Safety Signs

Fire safety signs ensure that personnel can respond quickly and efficiently in case of a fire emergency, protecting lives and property. Proper fire safety instructions enable workers to extinguish fires at their inception.

Commitment to Safety in the Spinning Industry

Spinning safety signs represent a commitment to the well-being of workers. These signs support successful and safe operations by highlighting risk assessment and fire safety in various areas of the spinning mill. They remain crucial until the cotton is transformed into yarn, ensuring a safe working environment.

Conclusion:

The spinning industry is a vital sector that produces essential clothing items. Minimizing risks associated with spinning production is paramount. Safety signs act as steadfast sentinels, ensuring that workers can perform their duties safely. They reflect the industry’s dedication to safeguarding its greatest asset: its workforce.

For any spinning company, implementing comprehensive safety signs and fire safety evacuation plans is essential. Our spinning safety signs are manufactured according to international standards, ensuring the highest level of safety and compliance.

#SpinningSafety #WorkplaceSafety #SpinningCompliance #SafetyFirst #RiskAssessment #FireSafety #HealthSafety #CottonProcessing #SafetyGuidelines #SafetyAwareness #ProtectiveMeasures #SafetyAtWork #SafetyCulture #SafeTextiles #IndustrialSafety #SafetyInnovation #SafetyStandards #SafeWorkEnvironment #ProtectingWorkers #SafetyCompliance #SafetyGuidelines

OSHA Safety Signs

OSHA Safety Signs: A Comprehensive Guide to Ensuring Workplace Safety

Understanding the critical role of OSHA safety signs in the workplace is essential. These signs fall into four main categories: Danger, Warning, Caution, and Notification. Each serves a unique purpose in addressing varying levels of risk. Why are OSHA standards vital for safeguarding employees and workers?

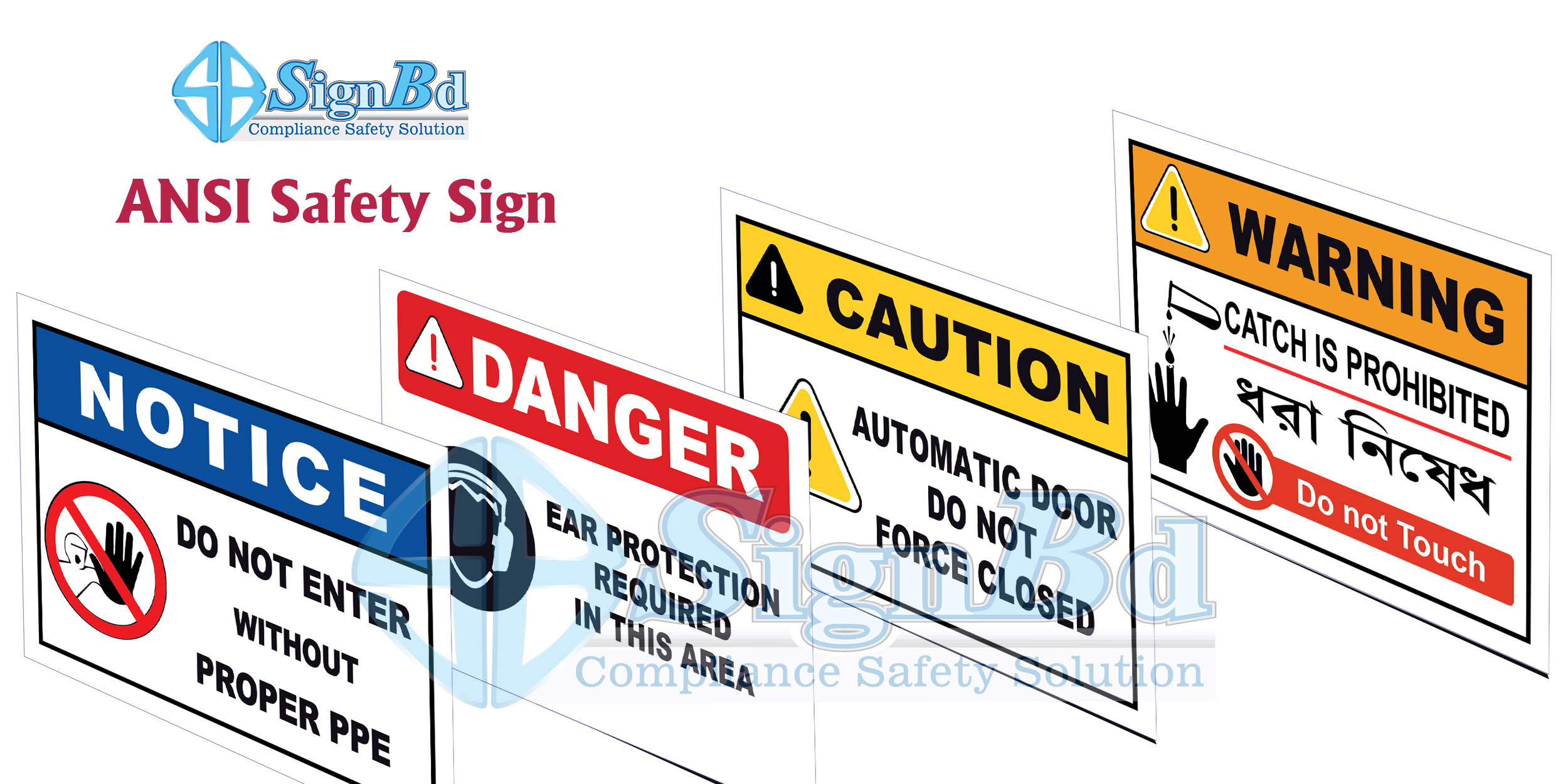

ANSI Safety Sign

Understanding and Implementing ANSI Safety Sign Standards

The American National Standards Institute (ANSI) sets the benchmark for safety and accident prevention through comprehensive guidelines, particularly ANSI Z535.4-2011 (R2017). These guidelines are crucial for creating effective safety signs and labels across various industries. Whether it’s a label or a sign, the primary goal is to convey critical safety information to comply with ANSI standards. Let’s delve into the importance of adhering to ANSI safety sign standards.

ISO Safety Signs

Enhancing Workplace Safety with ISO Safety Signs

In the modern workplace, safety is of utmost importance. One of the key elements in maintaining a safe environment is the use of ISO safety signs. These signs, governed by the ISO 7010 standard, are crucial for effective safety communication. They play a significant role in preventing accidents, ensuring fire safety, communicating health hazards, and facilitating emergency evacuations.

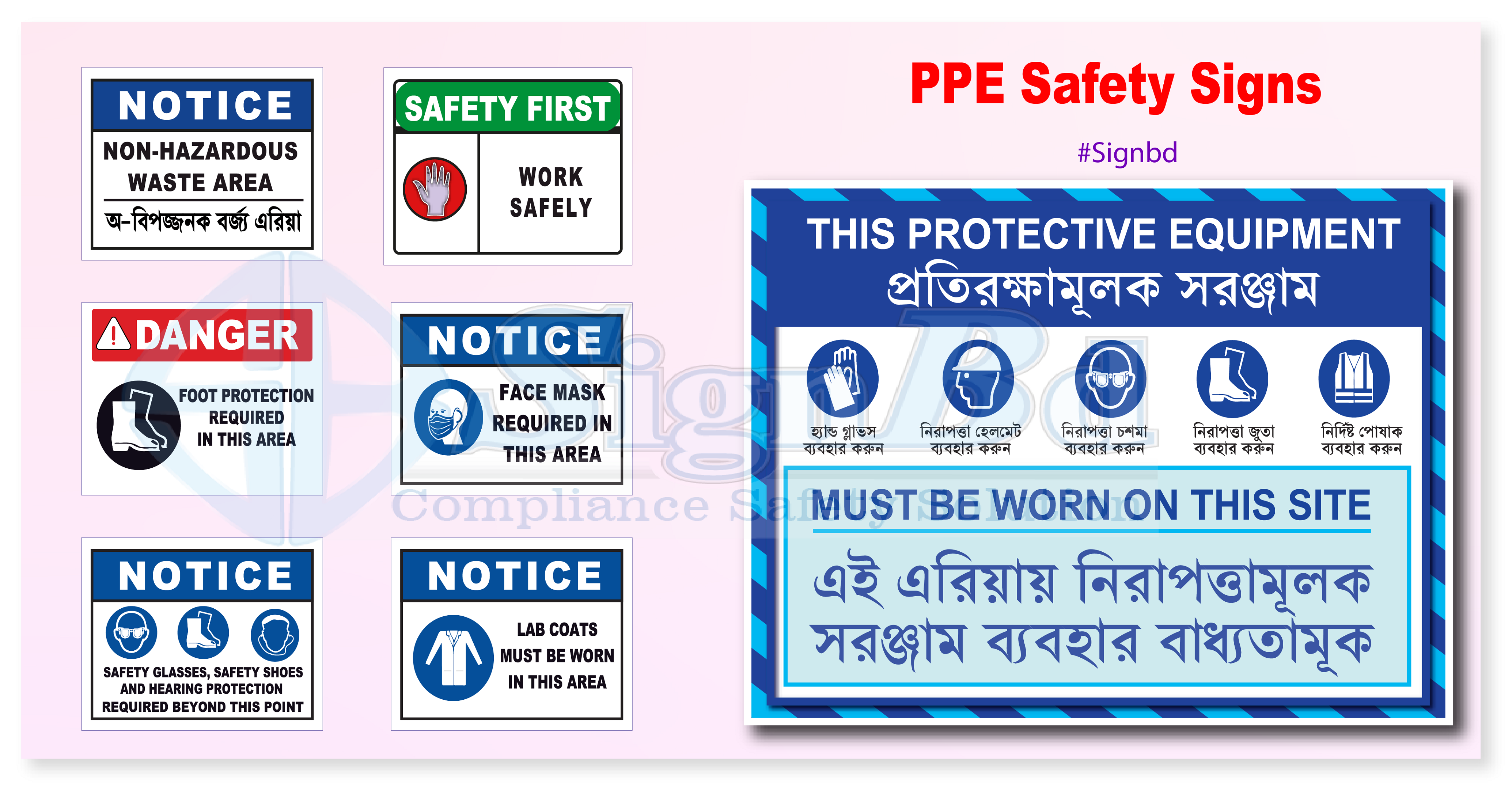

PPE Safety Sign

The Importance of PPE Safety Signs in the Workplace

What is PPE?

Personal Protective Equipment (PPE) refers to specialized clothing and equipment designed to shield the wearer from injury or infection. This includes items like protective clothing, helmets, gloves, goggles, and boots. PPE is crucial in various workplaces to protect workers from potential hazards such as chemical, radiological, physical, electrical, and mechanical dangers. Ensuring the use of PPE significantly reduces the risk of serious injuries and illnesses in the workplace.

The Essential Role of Caution Signs in Workplace Safety

Ensuring Safety Across Various Industries

In the world of industrial and manufacturing organizations, safety is paramount. Caution signs play an essential role in ensuring the well-being of employees and workers. This article delves into the significance of warning signs across various industries and how they contribute to workplace safety.

Bilingual Safety Signs

Danger Signs, Warning Signs, Mandatory Signs, Caution Signs, Prohibition Signs

Enhancing Workplace Safety with Bilingual Safety Signs

Introduction: The Importance of Bilingual Safety Signs

Effective communication in the workplace is crucial for ensuring safety, especially in multilingual environments. Bilingual safety signs are essential tools that help convey important safety information to all employees, regardless of their native language. This article delves into the significance of bilingual safety signs, including danger signs, warning signs, mandatory signs, and caution signs, across various industries.

Why Bilingual Safety Signs Matter

Bilingual safety signs act as universal communicators, ensuring that crucial safety information is accessible to everyone. Industries such as garment factories, dyeing and washing facilities, pharmaceutical companies, and tanneries rely heavily on these signs to maintain a safe working environment. These signs are not just visual aids; they are integral components of workplace safety.

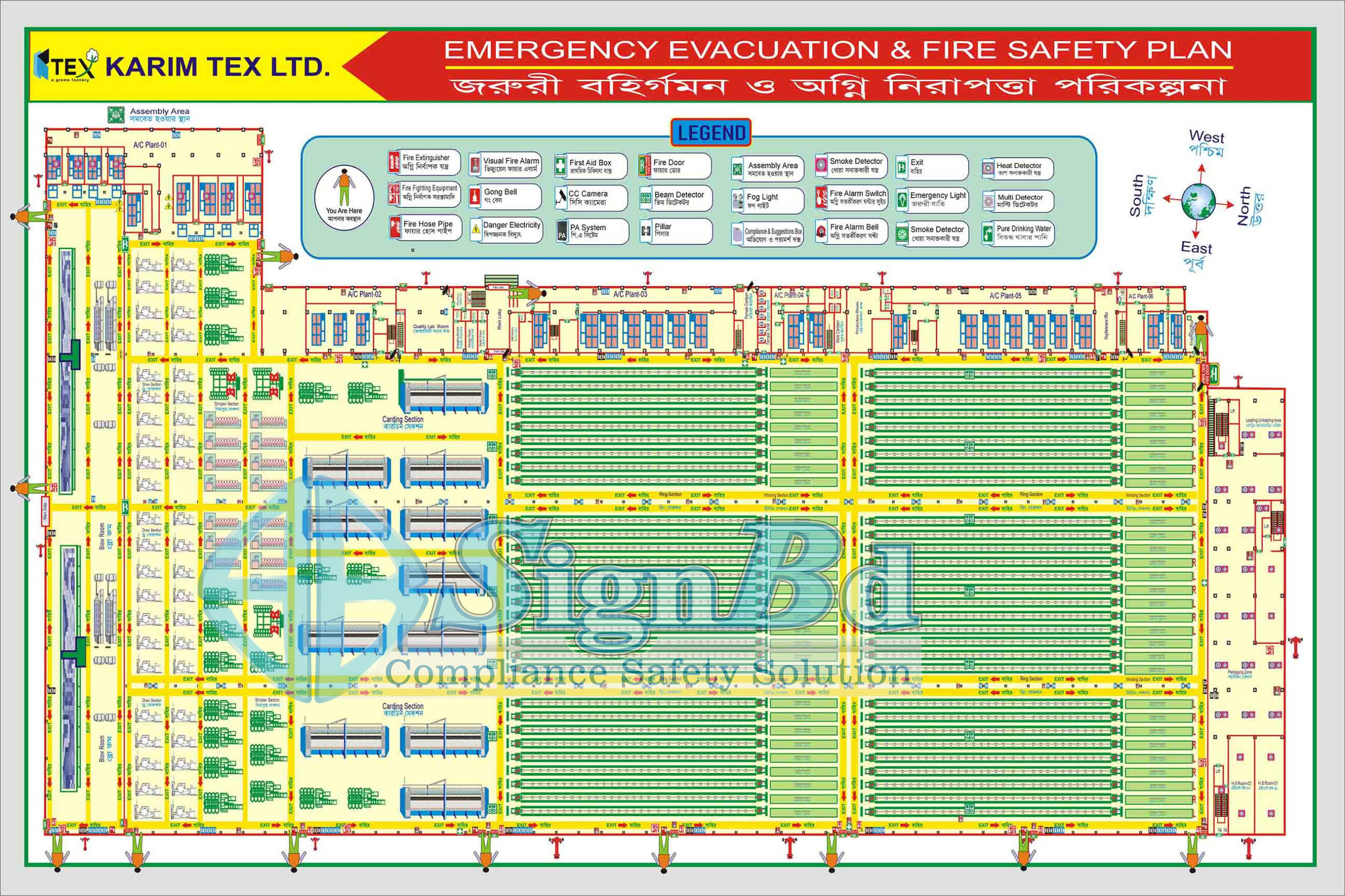

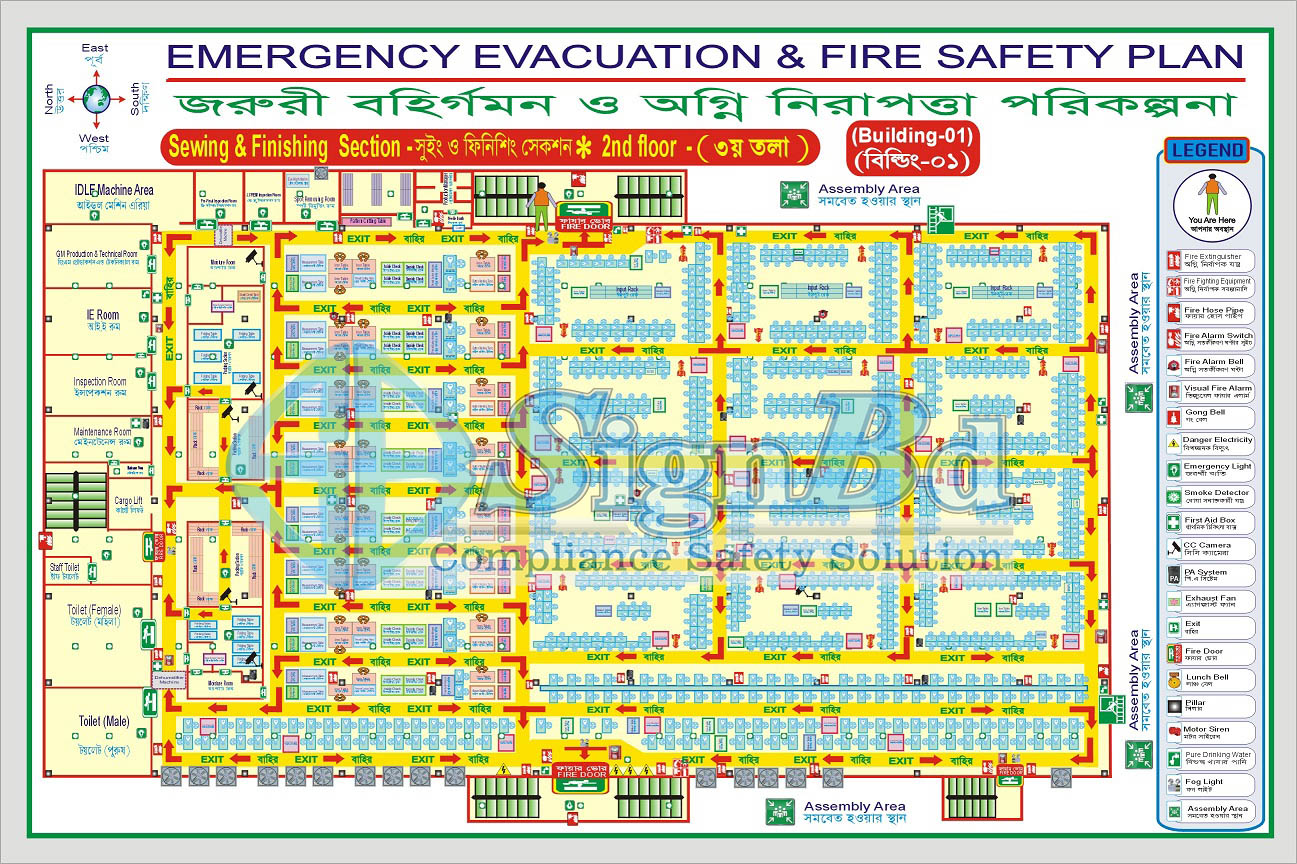

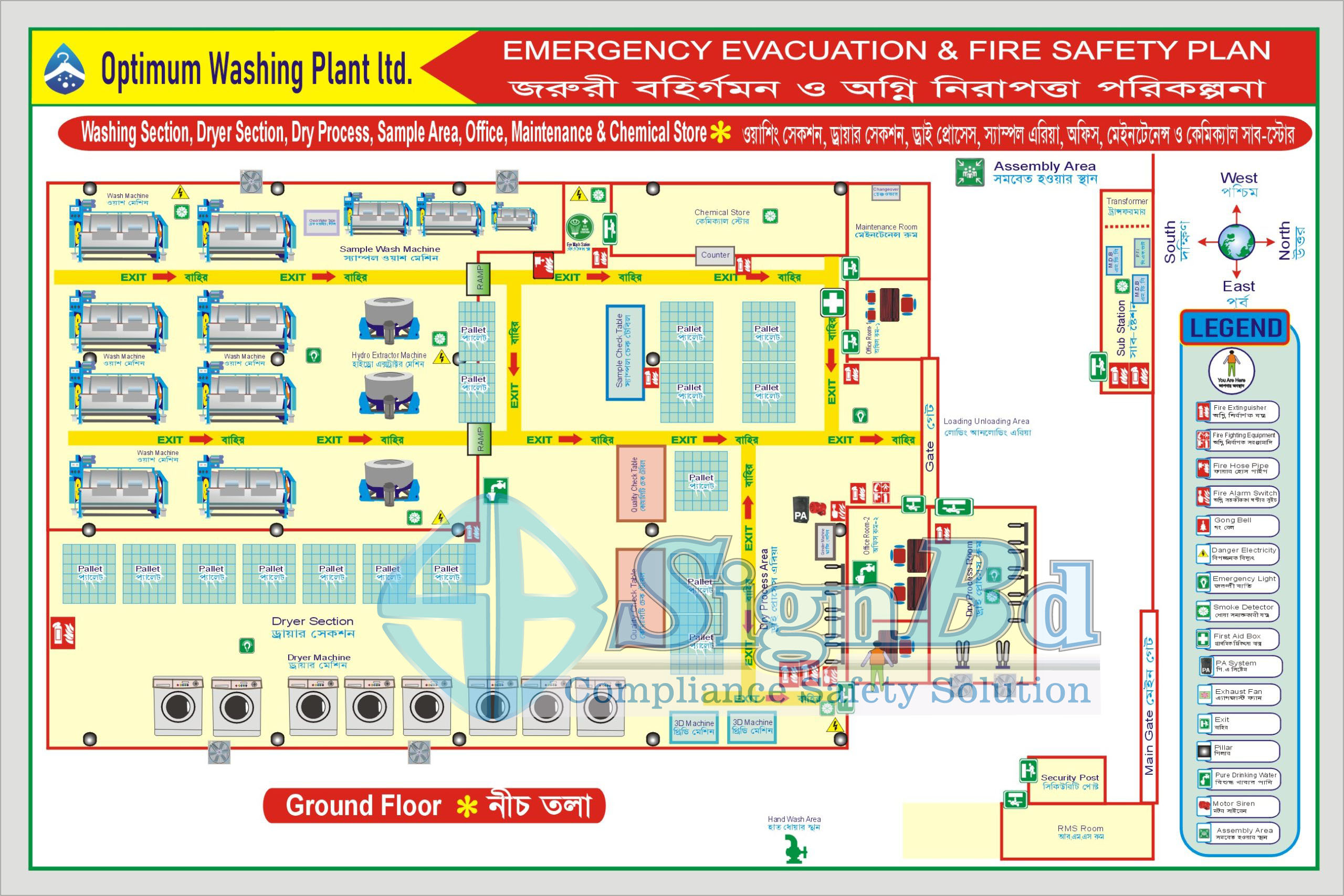

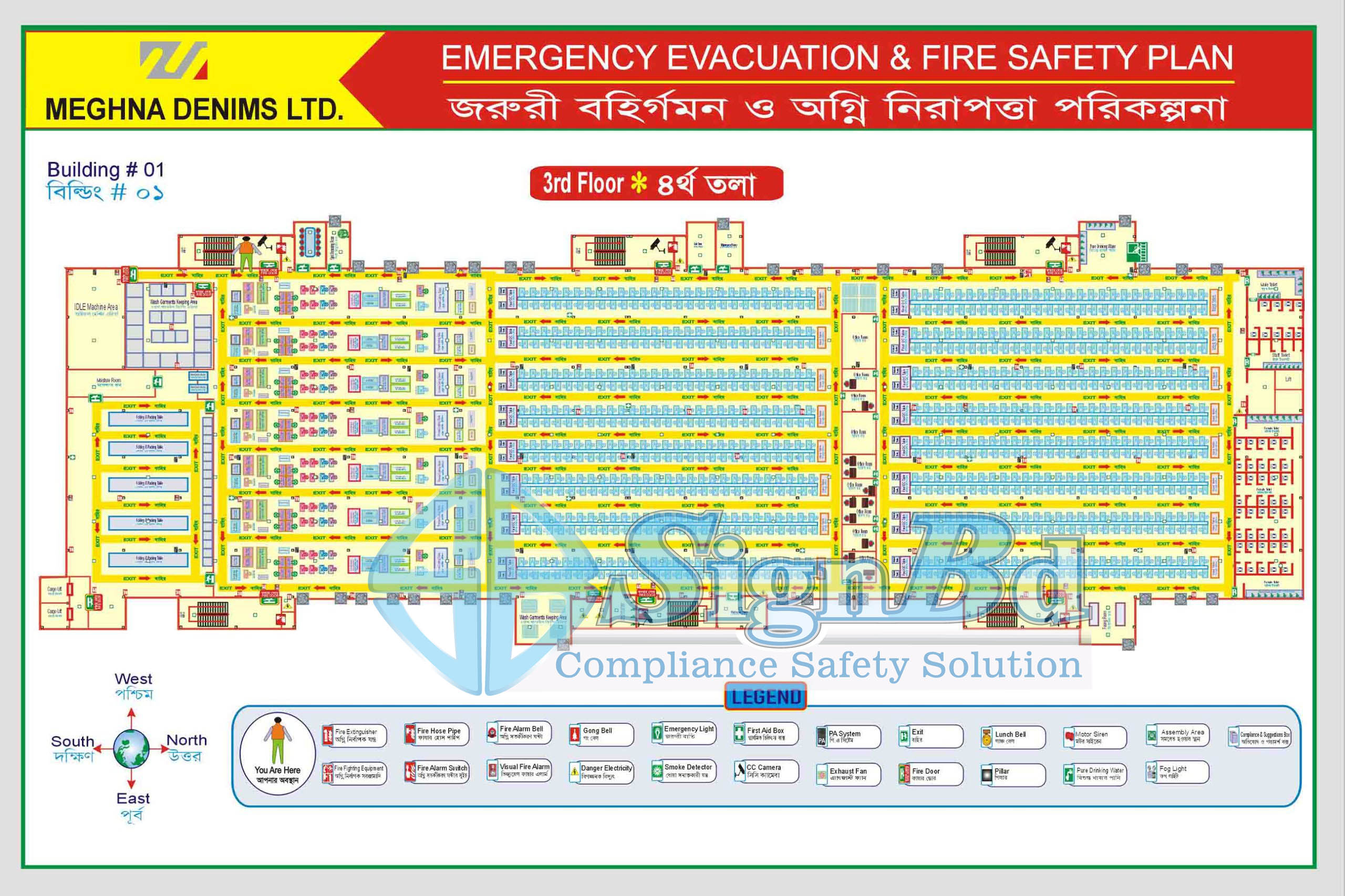

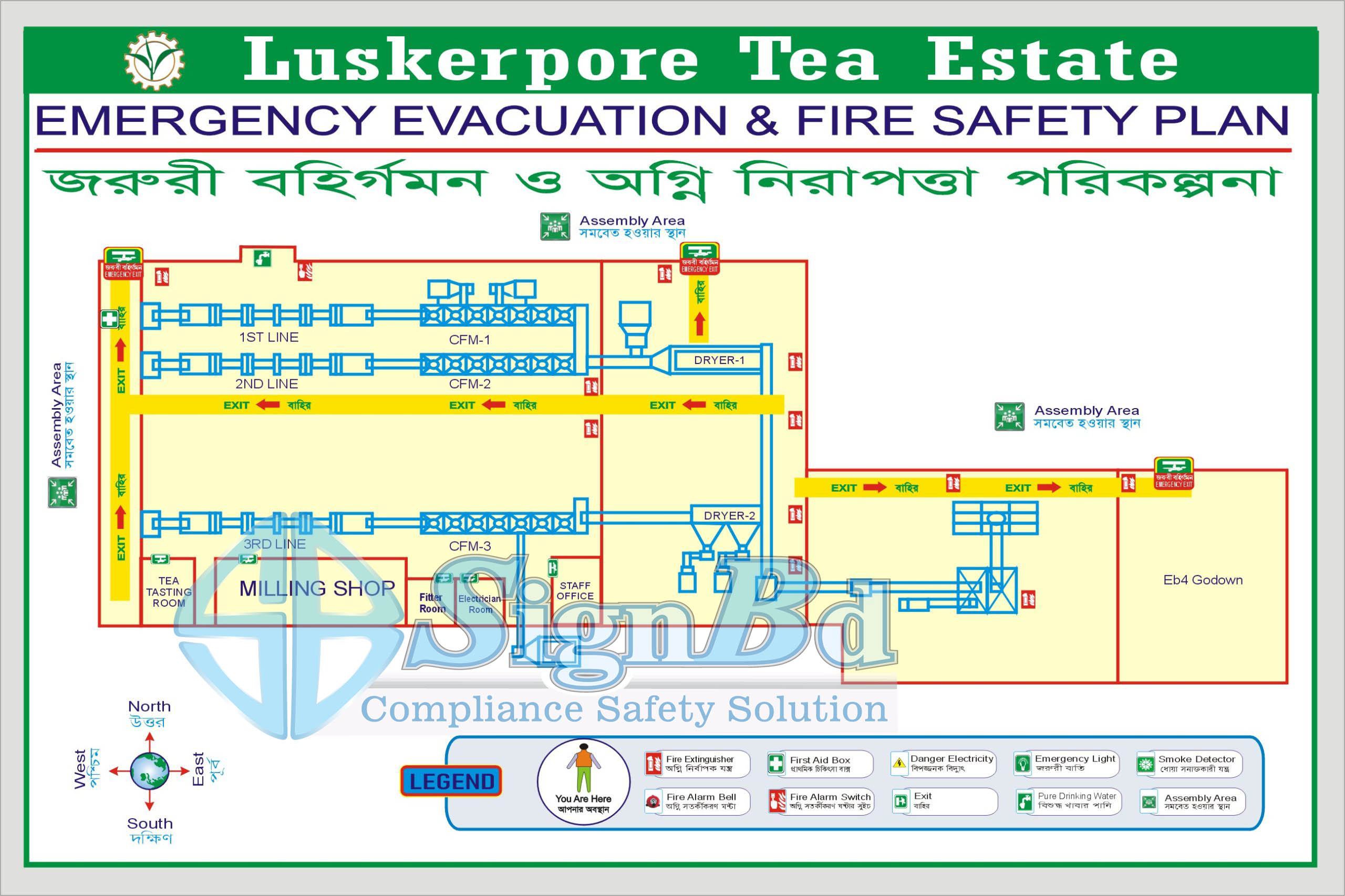

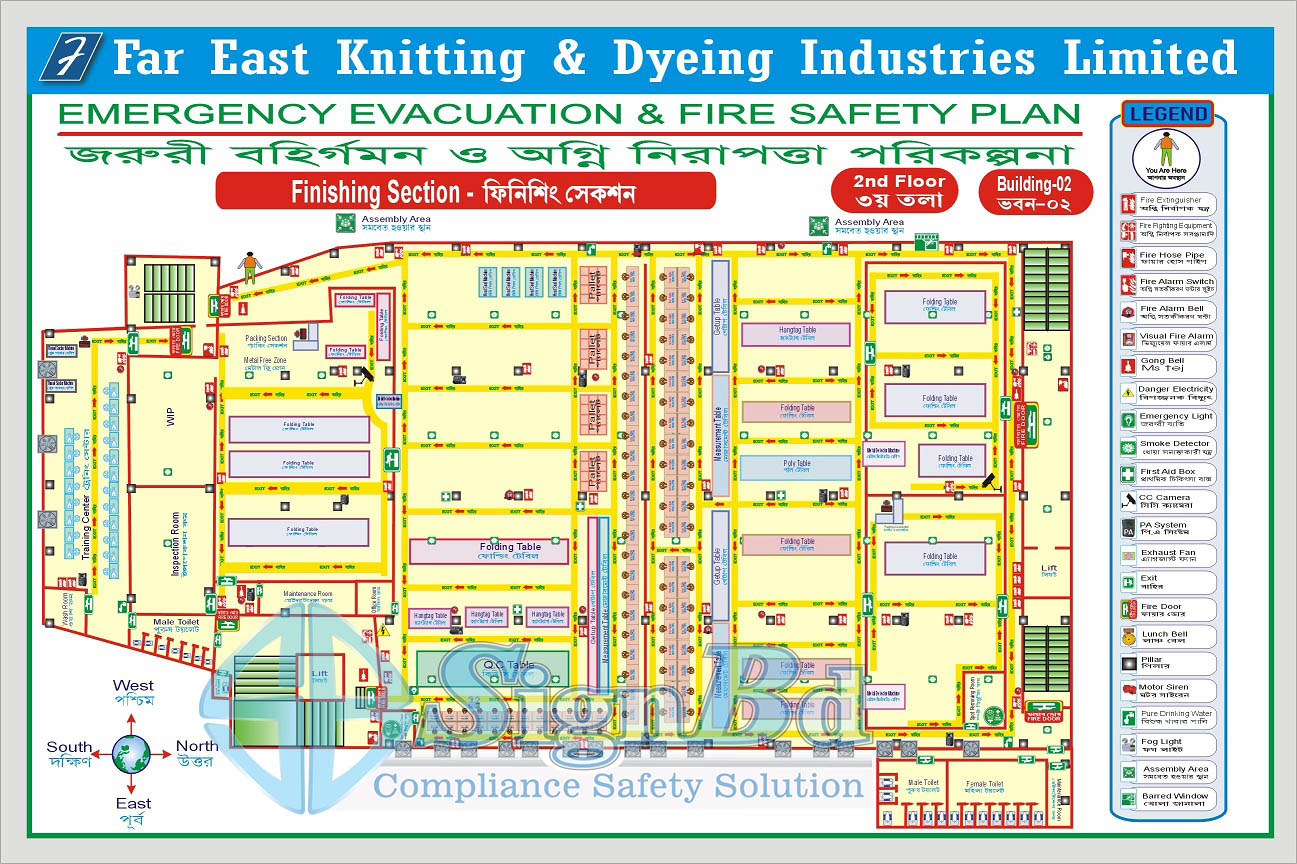

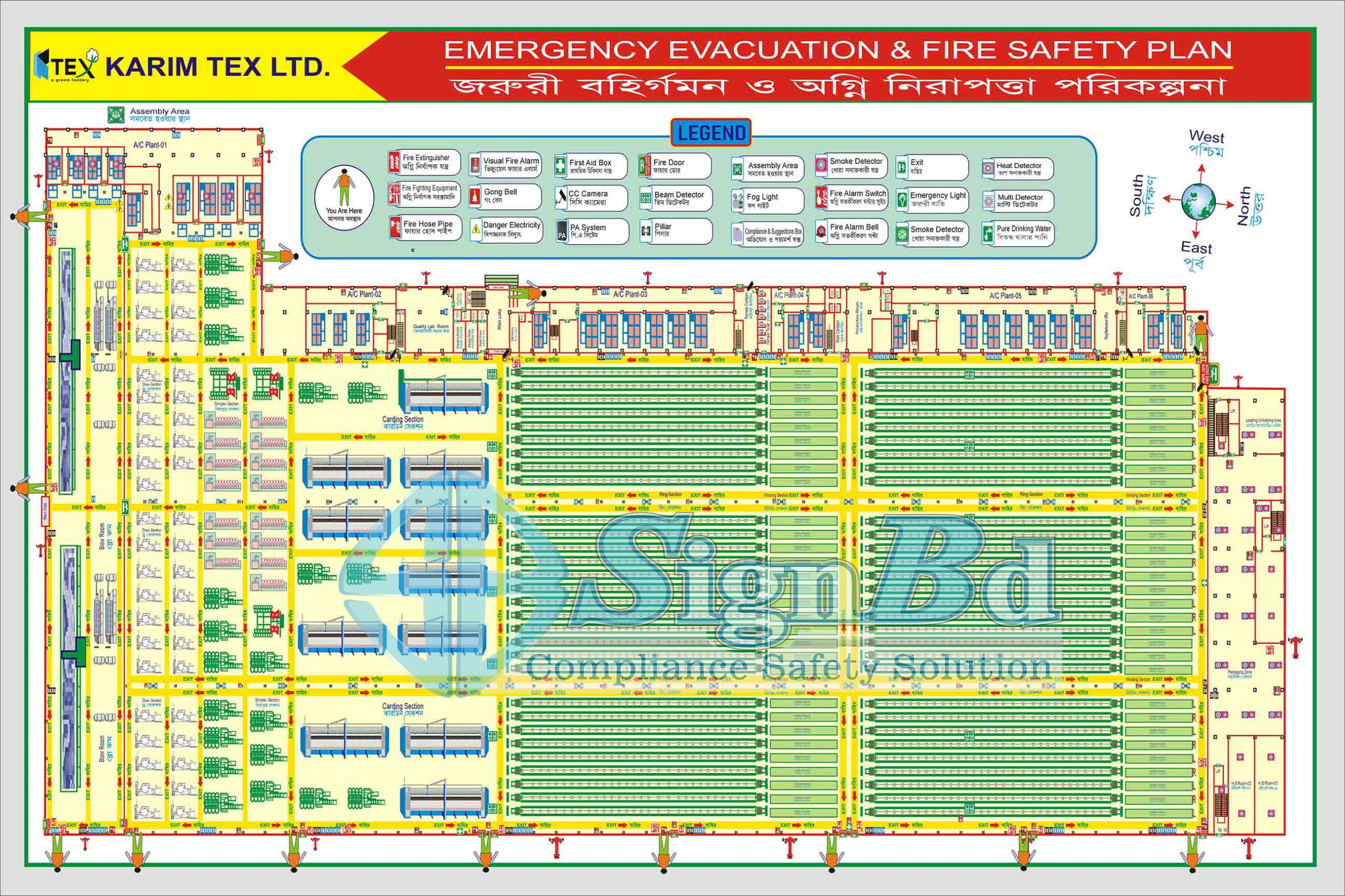

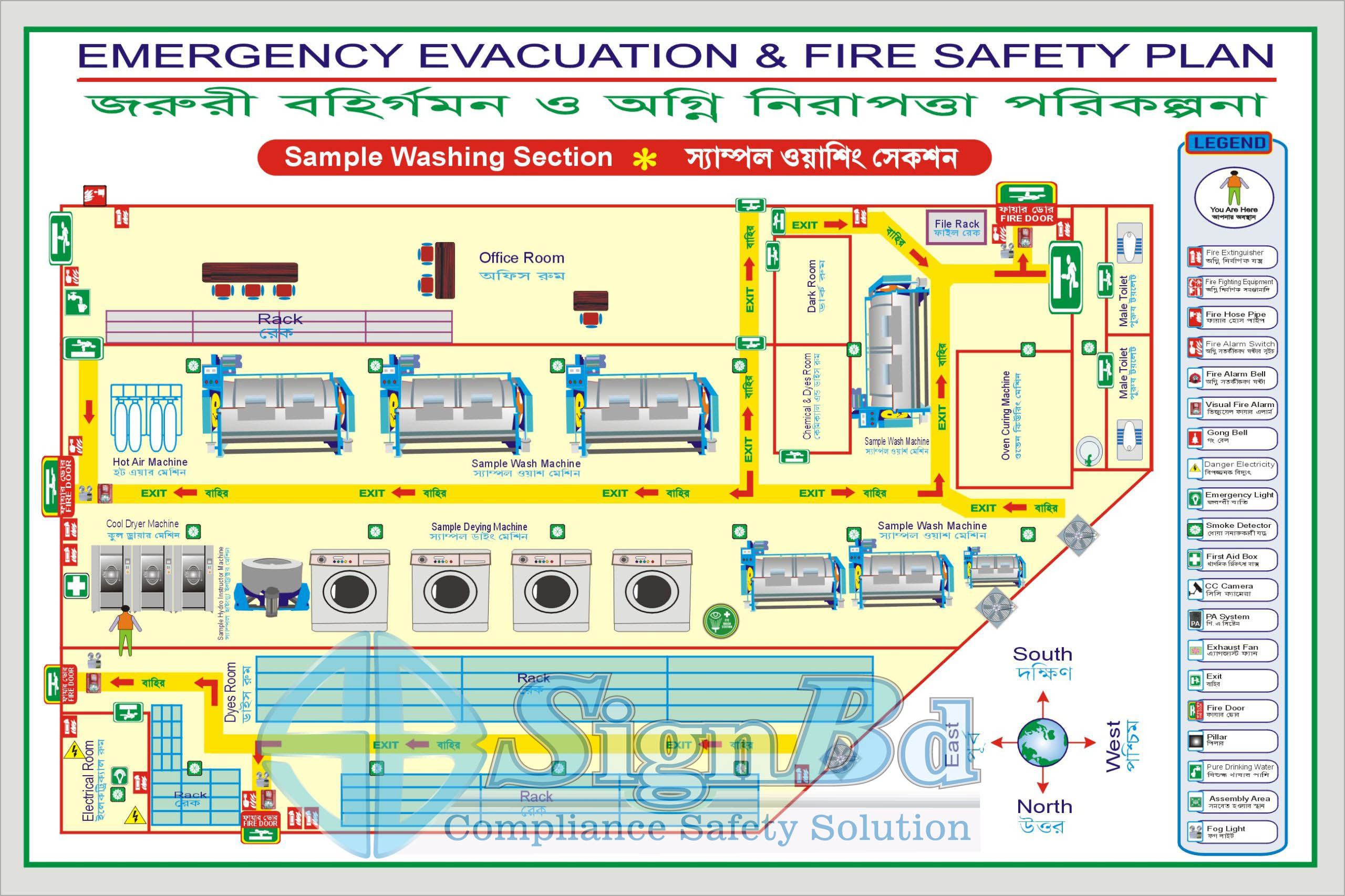

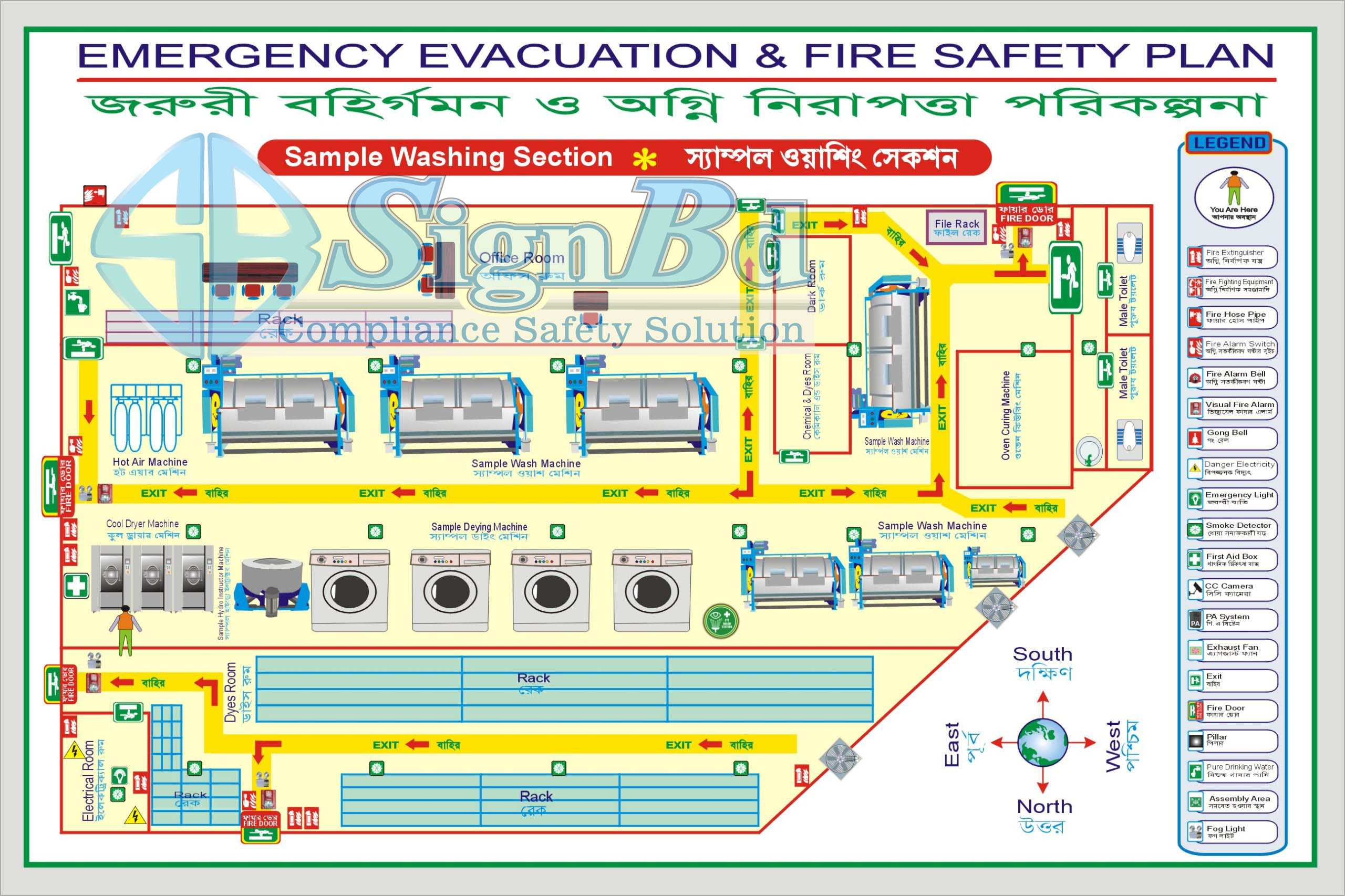

Your Custom Evacuation Floor Plan Design

The Essential Guide to Fire Safety Evacuation Floor Plans

Ensuring the safety of employees in factories, industries, and companies worldwide hinges on having a meticulously designed fire safety evacuation floor plan. This article delves into the critical nature of these plans, particularly in compliance with US and European standards, and emphasizes their role in safeguarding worker and personnel safety.

Gate in Touch:

Copyright © 2006 | Powered by signbd