+8801600371198

sign_bd@yahoo.com

Account Login

Home>>Blog>>What We Can Do to Deal with Earthquakes

What We Can Do to Deal with Earthquakes

What We Can Do to Deal with Earthquakes

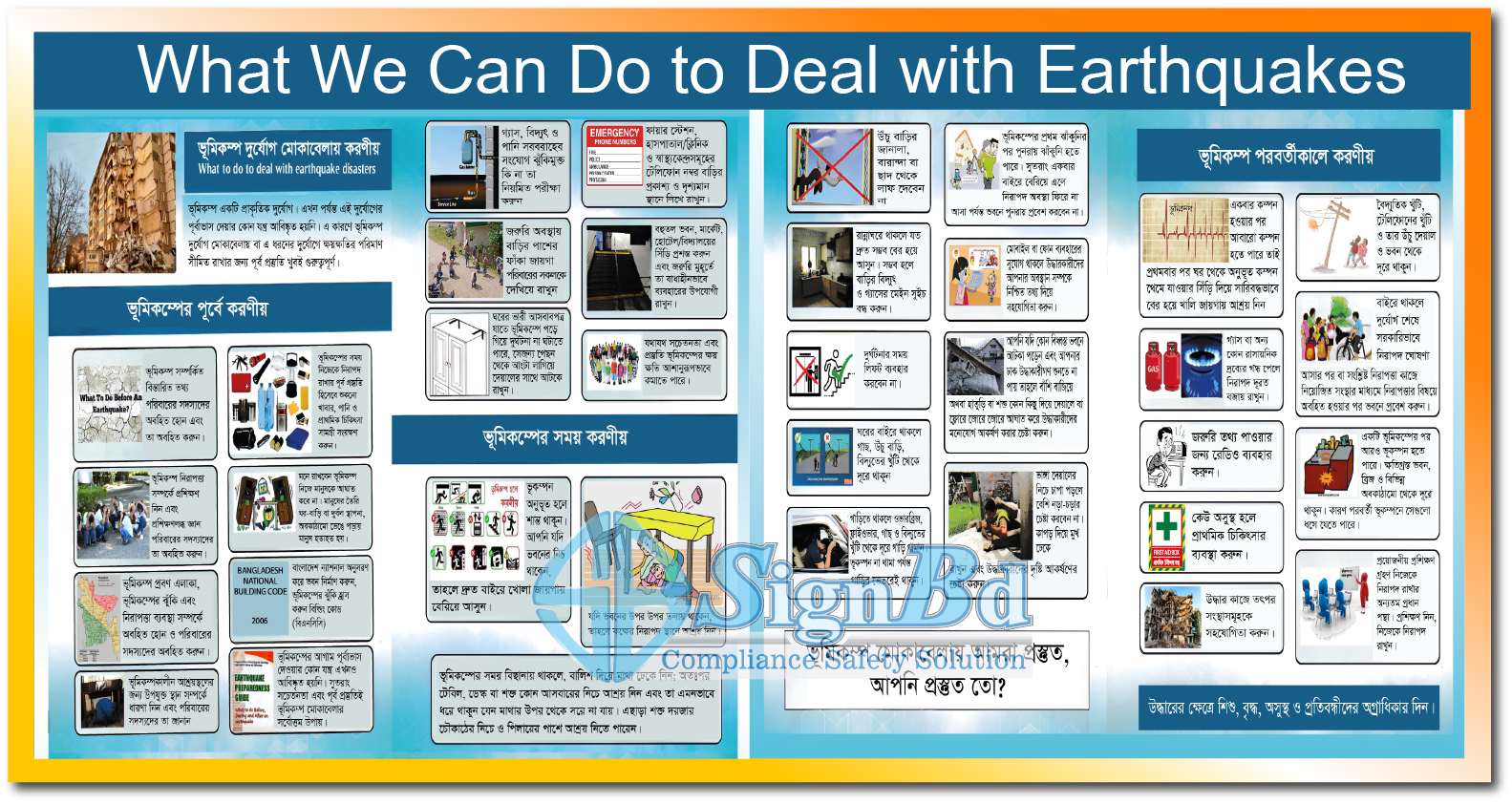

Earthquakes are among the most destructive natural hazards, posing serious risks to human life, infrastructure, and industrial operations. For international standard garment factories in Bangladesh, where thousands of workers operate daily within large production facilities, earthquake preparedness is not optional—it is a critical responsibility. In this article, we explain what we can do to deal with earthquakes by adopting global best practices, safety engineering, worker training, and compliance-driven disaster management strategies that align with international standards.

Understanding Earthquake Risks in Bangladesh’s Industrial Sector

Bangladesh is located near several active tectonic fault lines, making seismic activity a real and ongoing threat. For export-oriented garment factories, earthquakes can cause structural collapse, fire outbreaks, chemical spills, and mass injuries, disrupting supply chains and endangering lives. Understanding these risks is the foundation of what we can do to deal with earthquakes in a systematic and sustainable way.

Why Earthquake Preparedness Matters for Garment Factories

Protecting Human Lives

Our first priority is worker safety. With thousands of employees working in multi-story buildings, even a moderate earthquake can become catastrophic without proper planning.

Ensuring Business Continuity

International buyers demand uninterrupted production and strict compliance. Earthquake readiness helps factories recover faster and maintain buyer confidence.

Meeting International Compliance Standards

Organizations such as Accord, Alliance, ISO, and BSCI require factories to implement disaster preparedness plans, including earthquake risk mitigation.

What We Can Do to Deal with Earthquakes: A Strategic Framework

Seismic-Resistant Factory Design

One of the most effective actions in what we can do to deal with earthquakes is ensuring that factory buildings are structurally sound.

Key Measures

- Construction based on BNBC and international seismic codes

- Retrofitting older buildings with shear walls, base isolators, and reinforced columns

- Regular third-party structural integrity audits

These measures significantly reduce the risk of collapse during seismic events.

Comprehensive Risk Assessment and Hazard Mapping

Identifying Vulnerable Zones

We conduct detailed seismic risk assessments to identify weak points such as stairwells, storage areas, machinery zones, and emergency exits.

Hazard Mapping

Factories should maintain updated earthquake hazard maps clearly displayed on each floor, guiding workers toward safe evacuation routes.

Emergency Response Planning for Earthquakes

Developing an Earthquake Emergency Action Plan (EEAP)

A well-documented plan is central to what we can do to deal with earthquakes effectively.

Core Components

- Emergency command structure

- Evacuation procedures

- Assembly points

- Medical response protocols

- Communication hierarchy

The plan must be written, accessible, and regularly updated.

Clear Evacuation Routes and Safe Assembly Points

Evacuation Infrastructure

- Wide, unobstructed staircases

- Glow-in-the-dark directional signage

- Emergency lighting with backup power

Assembly Points

Open, debris-free zones away from buildings are designated as safe assembly areas, clearly marked and known to all workers.

Training and Awareness: Empowering the Workforce

Regular Earthquake Drills

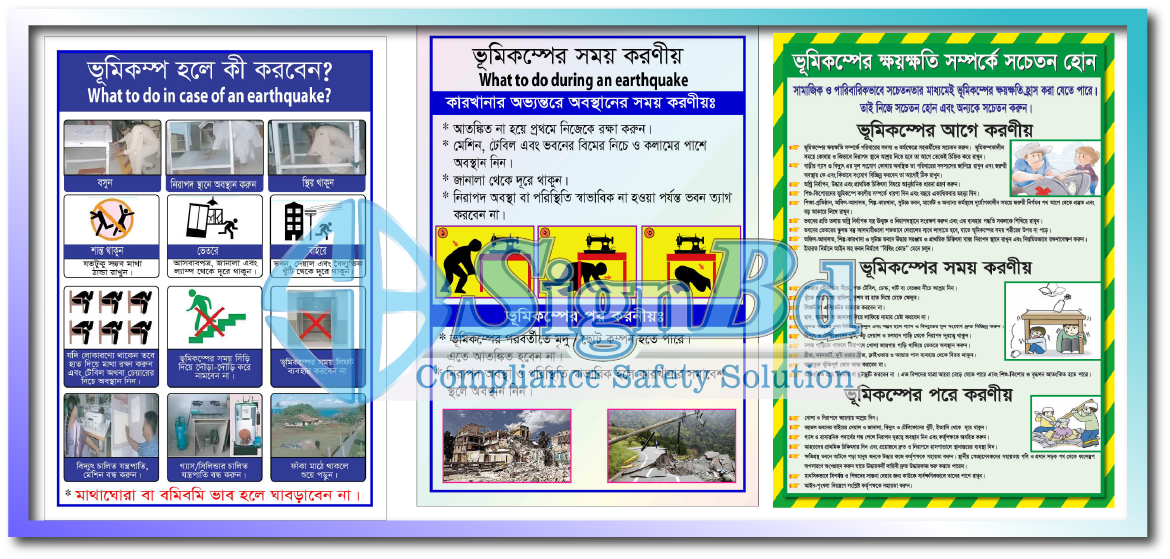

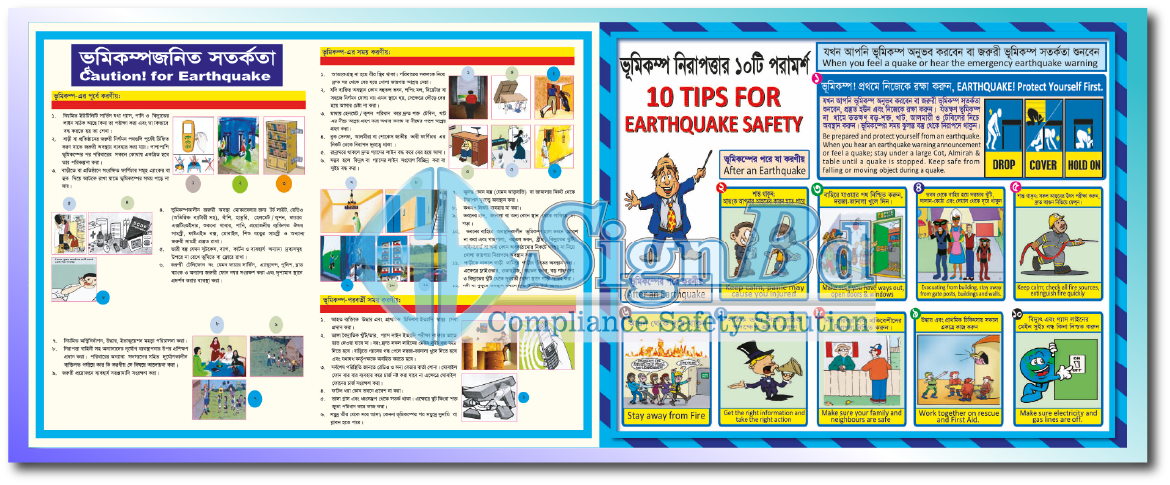

Conducting mock earthquake drills at least twice a year is essential. These drills simulate real-life scenarios, helping workers respond calmly and efficiently.

Worker Education Programs

We ensure that every worker understands:

- Drop, Cover, and Hold On techniques

- Safe evacuation behavior

- How to assist injured colleagues

Multilingual training materials ensure inclusivity for all workers.

Early Warning Systems and Technology Integration

Seismic Monitoring Systems

Advanced factories integrate seismic sensors and early warning systems that provide critical seconds to shut down machinery and initiate evacuation.

Automated Safety Controls

- Automatic gas and power shut-off systems

- Fire suppression activation

- Machinery lockdown protocols

Technology plays a vital role in what we can do to deal with earthquakes proactively.

Fire Safety and Secondary Hazard Prevention

Earthquakes often trigger fires, making fire safety inseparable from earthquake preparedness.

Fire Risk Mitigation

- Flexible gas pipelines

- Fire-resistant materials

- Regular inspection of electrical systems

Integrated Fire and Earthquake Response

Emergency teams are trained to manage compound disasters, ensuring coordinated response during chaotic situations.

Medical Preparedness and First Aid Readiness

On-Site Medical Facilities

Factories must maintain:

- Fully stocked first aid stations

- Stretchers and emergency kits

- Trained first responders on every floor

Coordination with Local Hospitals

Pre-established partnerships with nearby hospitals ensure rapid medical evacuation when necessary.

Supply Chain Resilience and Post-Earthquake Recovery

Business Continuity Planning

A robust Business Continuity Plan (BCP) outlines how operations will resume after an earthquake.

Key Focus Areas

- Data backup and IT recovery

- Alternative production sites

- Supplier contingency strategies

Damage Assessment and Rapid Repair

Post-earthquake inspections by certified engineers allow factories to resume operations safely and efficiently.

Regulatory Compliance and Continuous Improvement

Adhering to National and International Standards

Compliance with BNBC, ILO, ISO 45001, and buyer-specific safety codes is mandatory.

Continuous Monitoring and Audits

Regular internal and external audits ensure preparedness strategies remain effective and up to date.

Our Responsibility Toward Sustainable Industrial Safety

Earthquake preparedness is not a one-time task; it is an ongoing commitment. By embedding safety into factory culture, investing in resilient infrastructure, and empowering workers, we demonstrate what we can do to deal with earthquakes responsibly and ethically.

For Bangladesh’s garment industry, proactive earthquake management protects lives, strengthens global trust, and ensures long-term sustainability.

Conclusion: What We Can Do to Deal with Earthquakes Effectively

By combining engineering excellence, strategic planning, workforce training, and technological innovation, we create safer garment factories that can withstand seismic challenges. What we can do to deal with earthquakes is clear: prepare comprehensively, act decisively, and continuously improve. This approach not only saves lives but also secures the future of Bangladesh’s globally significant garment sector.

Gate in Touch:

Copyright © 2006 | Powered by signbd