+8801600371198

sign_bd@yahoo.com

Account Login

Home>>All Chemical Safety Signs>>Chemical Storage Signs

Chemical Storage Signs

Ensuring Workplace Safety with Chemical Storage Signs: An Essential Guide

Proper signage is crucial for maintaining safety and compliance in workplaces that handle hazardous chemicals. Chemical storage signs play a significant role in safeguarding employees and ensuring regulatory adherence. This comprehensive guide delves into the importance of chemical storage signs, exploring their types, regulations, and essential precautions.

Types of Chemical Storage Signs

Chemical Storage Area Signs

Chemical storage area signs designate specific zones for storing chemicals, promoting organization and compliance with safety regulations. For multilingual environments, chemical storage area bilingual signs ensure that all employees understand the hazards.

Projecting Signs

To enhance visibility, chemical storage area projecting signs provide a three-dimensional aspect, making them visible from multiple angles.

Emergency Eye Wash Station Signs

These signs are crucial for directing individuals to emergency eye wash stations, ensuring a quick response in case of exposure to harmful substances.

Floor Signs, Tags, and Labels

From floor to ceiling, proper labeling and signage are essential for a safe work environment.

Chemical Storage Area Floor Signs

These signs help identify potential hazards in walkways, ensuring that employees can navigate safely.

Chemical Storage Tags and Labels

Accurate labeling is crucial for quick identification of stored substances. These tags and labels comply with OSHA regulations, facilitating a safe and organized storage system.

Personal Protective Equipment (PPE) Signs

In chemical storage areas, specific PPE is often required. Chemical storage area PPE signs guide workers on the necessary protective gear for safe handling of chemicals.

Recognizing Signs of Chemical Exposure

Understanding and recognizing the signs of exposure to improperly stored chemicals is vital. Exposure can lead to adverse health effects, including skin irritation, respiratory issues, and more severe conditions. Employers must educate workers about these signs to ensure a swift response and minimize potential risks.

Chemical Safety and Compatibility Guidelines

Some chemicals must not be stored together due to their reactivity. For instance, acids should be kept separate from substances sensitive to acids to prevent dangerous reactions. Additionally, certain chemicals, such as enzyme compounds, require cold storage and should not be kept at warm temperatures. Adhering to Material Safety Data Sheets (MSDS) and OSHA guidelines is essential for specific storage instructions.

Regulations and Compliance

OSHA Standards

The Occupational Safety and Health Administration (OSHA) has set stringent guidelines for chemical storage. Compliance with these standards is mandatory for workplace safety.

GHS and Hazard Communication

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) ensures consistent communication of chemical hazards globally. Proper signage plays a crucial role in this system.

Environmental Protection Agency (EPA) Guidelines

The EPA provides additional regulations for chemical storage, especially concerning environmental safety and spill prevention.

Importance of Chemical Storage Signs

Enhancing Workplace Safety

Chemical storage signs are integral to maintaining a safe work environment. They alert employees to potential hazards and provide clear instructions for safe handling and emergency procedures.

Facilitating Compliance

Adhering to regulatory standards with proper signage helps organizations avoid penalties and ensures a safer workplace for everyone.

Promoting Organizational Efficiency

Clear and accurate chemical storage signage aids in organizing storage areas, making it easier to locate and manage chemicals.

Implementing Chemical Storage Signage

Conducting a Risk Assessment

Before implementing signage, conduct a thorough risk assessment to identify all potential hazards and areas that require signage.

Choosing the Right Signs

Select signs that are compliant with OSHA and GHS standards. Consider the specific needs of your workplace, such as bilingual signs or projecting signs for better visibility.

Training Employees

Proper training on the importance and interpretation of chemical storage signs is crucial. Employees should be aware of the different types of signs and the actions they indicate.

FAQs About Chemical Storage Signs

What Are Chemical Storage Signs?

Chemical storage signs are labels, tags, and signage used to identify and communicate hazards associated with chemical storage areas.

Why Are Chemical Storage Signs Important?

They are essential for ensuring workplace safety, regulatory compliance, and efficient organization of chemicals.

How Do I Choose the Right Chemical Storage Signs?

Consider the specific hazards, regulatory requirements, and the layout of your storage area when selecting signs.

What Regulations Govern Chemical Storage Signs?

OSHA, GHS, and EPA guidelines primarily govern the use of chemical storage signs.

How Often Should Chemical Storage Signs Be Inspected?

Regular inspections, at least annually or whenever there is a change in chemical storage, are recommended.

Conclusion:

Implementing comprehensive chemical storage signage is paramount for maintaining a safe work environment. Understanding the different types of signs and their purposes enhances workplace safety and ensures compliance with regulations. By prioritizing proper chemical storage signage, employers can protect their employees, maintain the integrity of stored materials, and create a well-organized and compliant workplace.

Stay informed, follow the regulations, and prioritize the well-being of everyone at your facility.

#ChemicalStorage #SafetySigns #OSHACompliance #WorkplaceSafety #ChemicalHandling #PPE #ChemicalStorageGuidelines #SafetyFirst #MSDS #IndustrialSafety #EmergencyResponse #ChemicalCompatibility #BilingualSigns #FloorSigns #WorkplaceHealth #ChemicalLabels

OSHA Safety Signs

OSHA Safety Signs: A Comprehensive Guide to Ensuring Workplace Safety

Understanding the critical role of OSHA safety signs in the workplace is essential. These signs fall into four main categories: Danger, Warning, Caution, and Notification. Each serves a unique purpose in addressing varying levels of risk. Why are OSHA standards vital for safeguarding employees and workers?

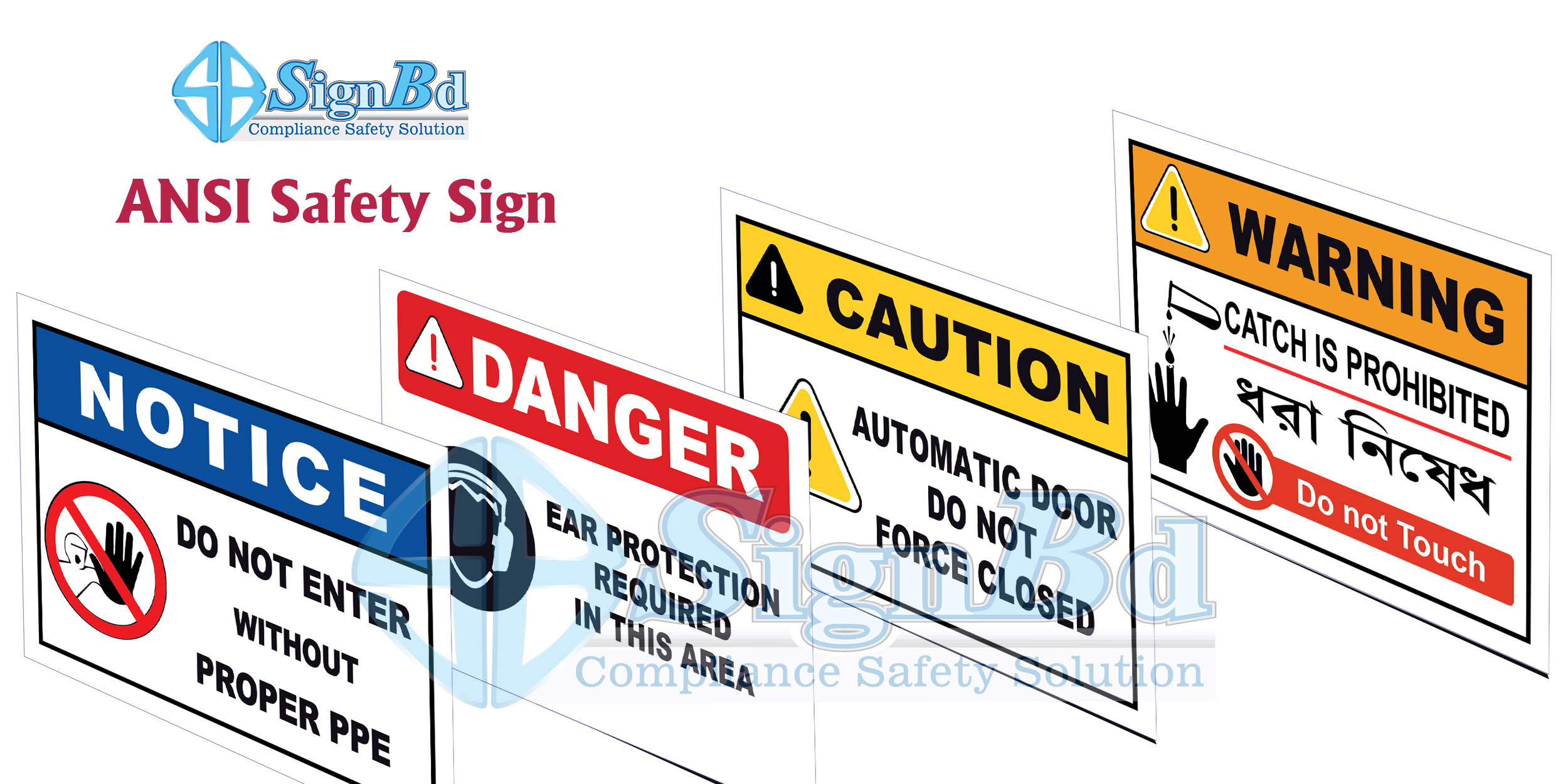

ANSI Safety Sign

Understanding and Implementing ANSI Safety Sign Standards

The American National Standards Institute (ANSI) sets the benchmark for safety and accident prevention through comprehensive guidelines, particularly ANSI Z535.4-2011 (R2017). These guidelines are crucial for creating effective safety signs and labels across various industries. Whether it’s a label or a sign, the primary goal is to convey critical safety information to comply with ANSI standards. Let’s delve into the importance of adhering to ANSI safety sign standards.

ISO Safety Signs

Enhancing Workplace Safety with ISO Safety Signs

In the modern workplace, safety is of utmost importance. One of the key elements in maintaining a safe environment is the use of ISO safety signs. These signs, governed by the ISO 7010 standard, are crucial for effective safety communication. They play a significant role in preventing accidents, ensuring fire safety, communicating health hazards, and facilitating emergency evacuations.

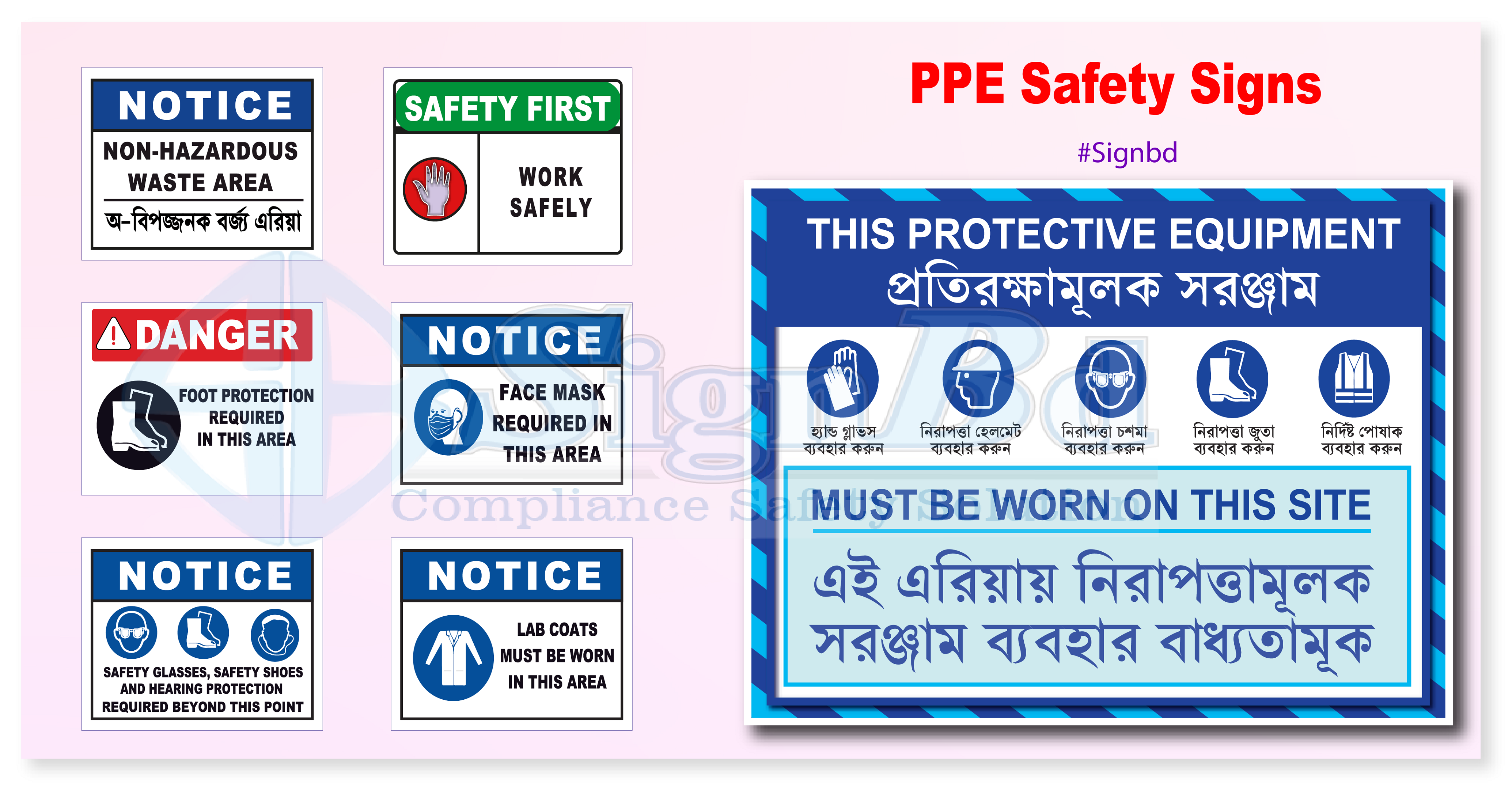

PPE Safety Sign

The Importance of PPE Safety Signs in the Workplace

What is PPE?

Personal Protective Equipment (PPE) refers to specialized clothing and equipment designed to shield the wearer from injury or infection. This includes items like protective clothing, helmets, gloves, goggles, and boots. PPE is crucial in various workplaces to protect workers from potential hazards such as chemical, radiological, physical, electrical, and mechanical dangers. Ensuring the use of PPE significantly reduces the risk of serious injuries and illnesses in the workplace.

The Essential Role of Caution Signs in Workplace Safety

Ensuring Safety Across Various Industries

In the world of industrial and manufacturing organizations, safety is paramount. Caution signs play an essential role in ensuring the well-being of employees and workers. This article delves into the significance of warning signs across various industries and how they contribute to workplace safety.

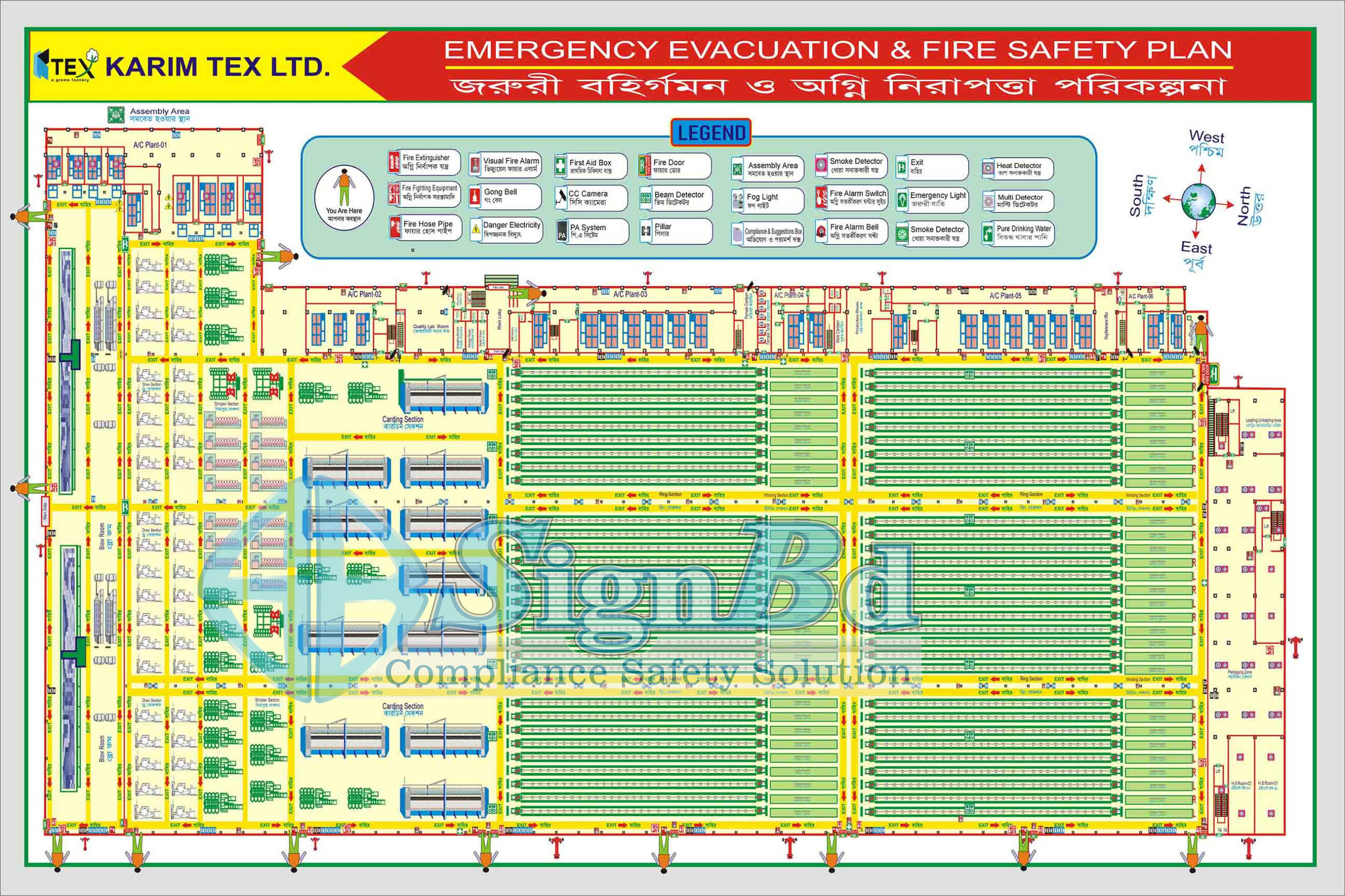

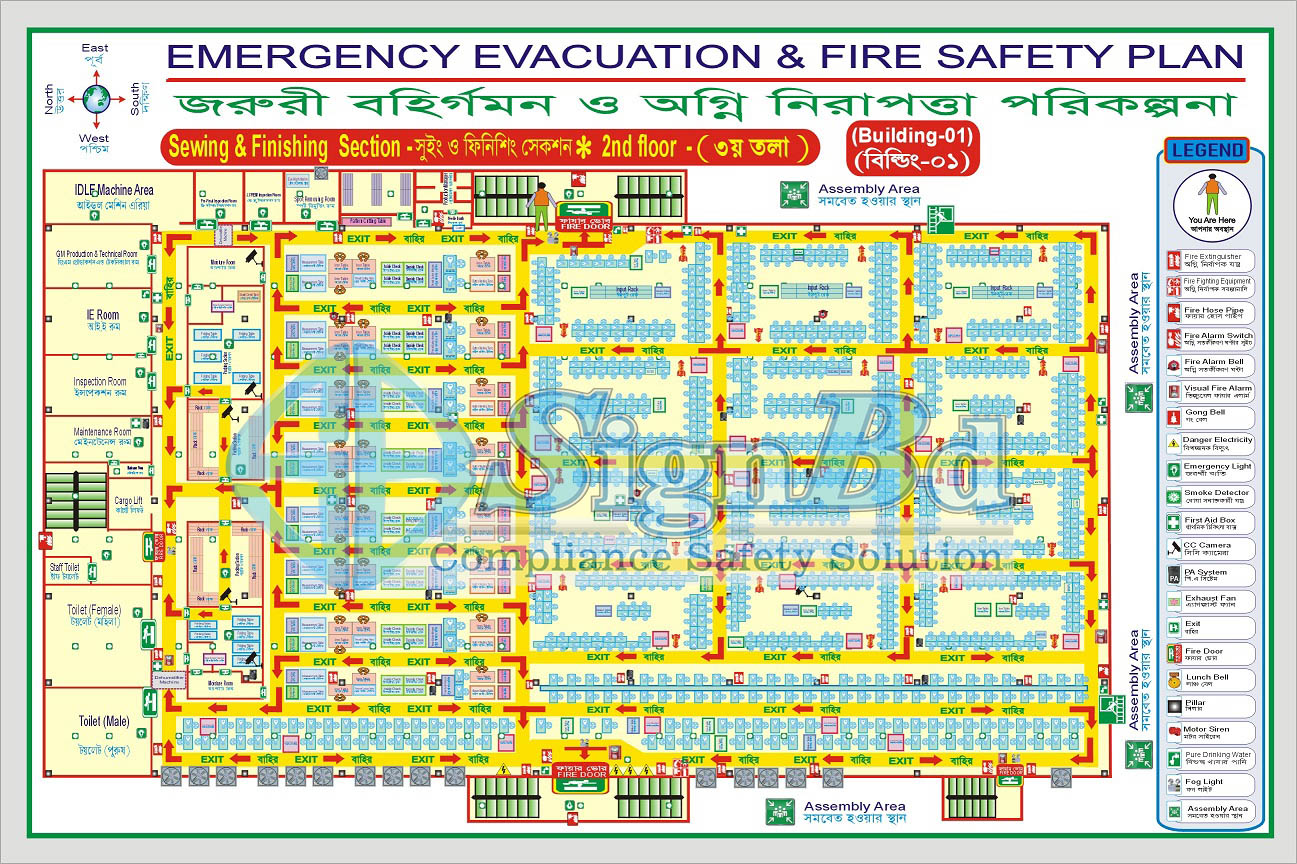

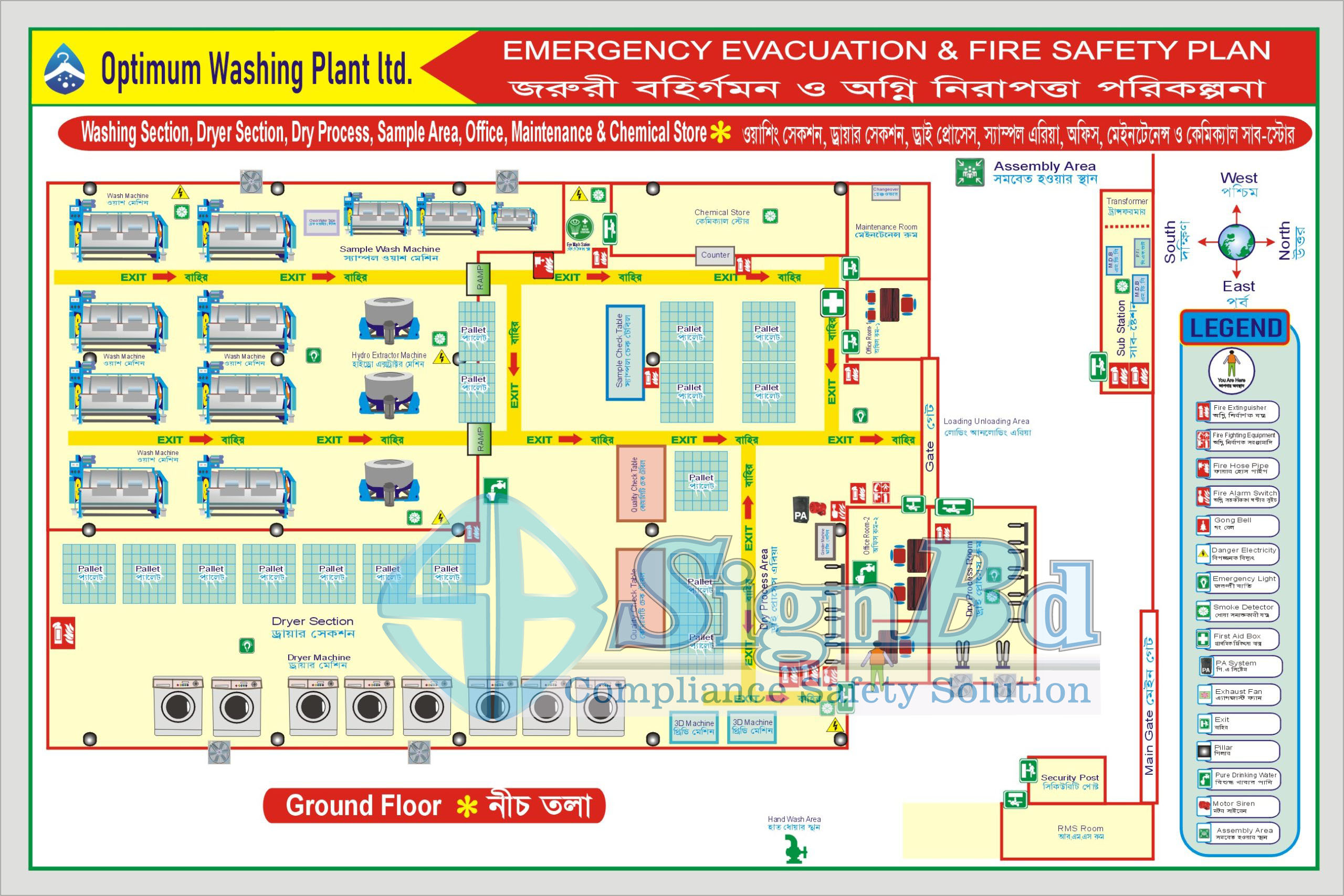

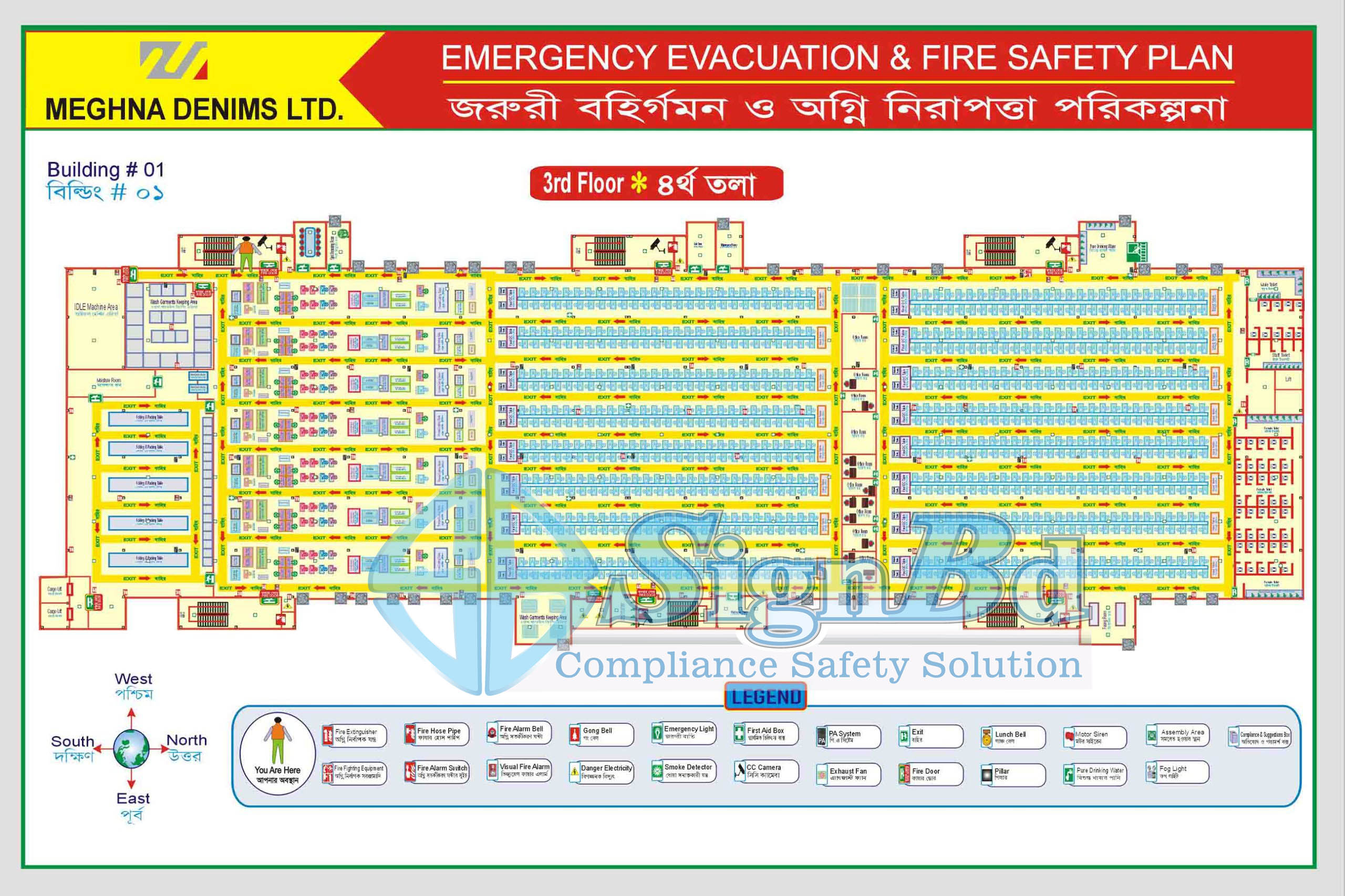

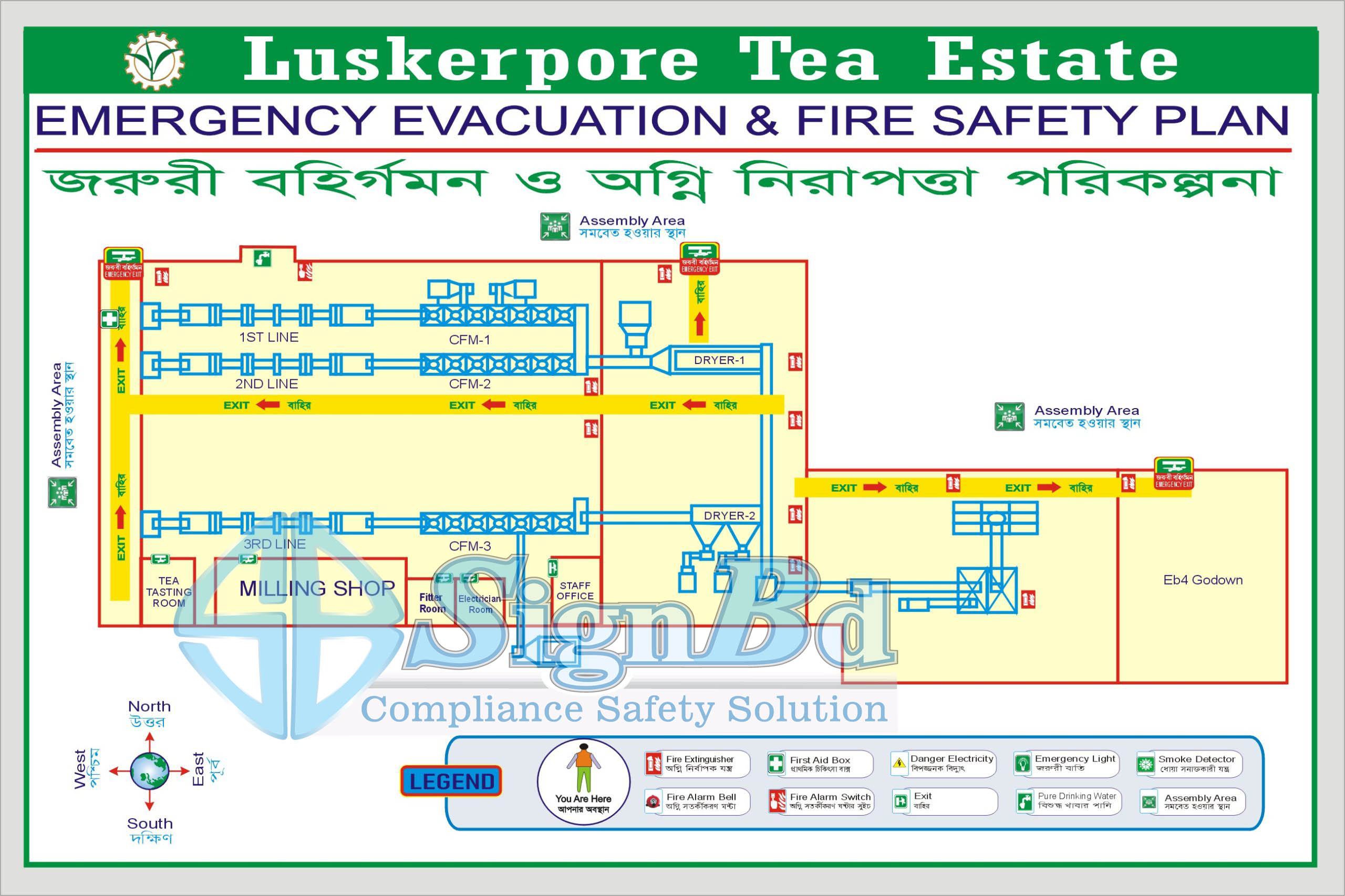

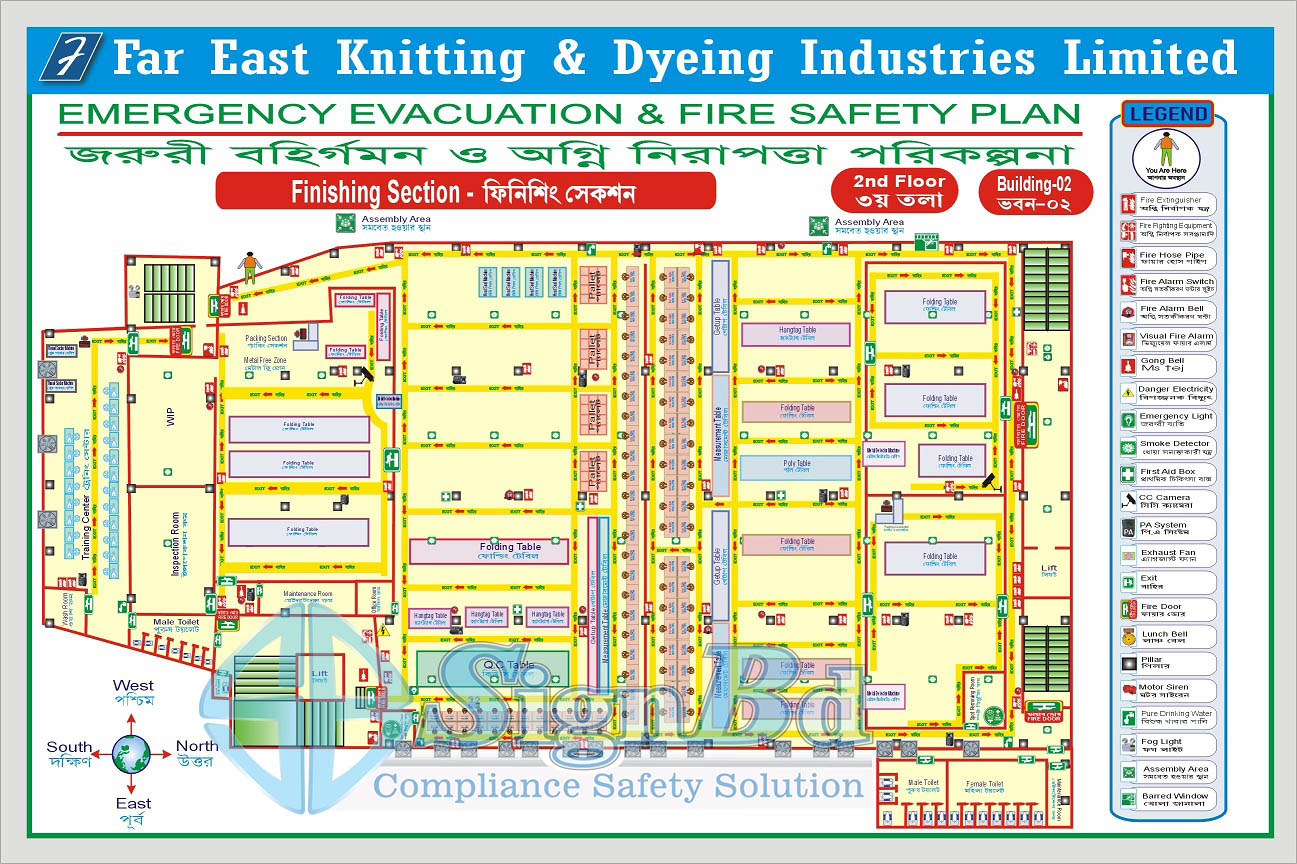

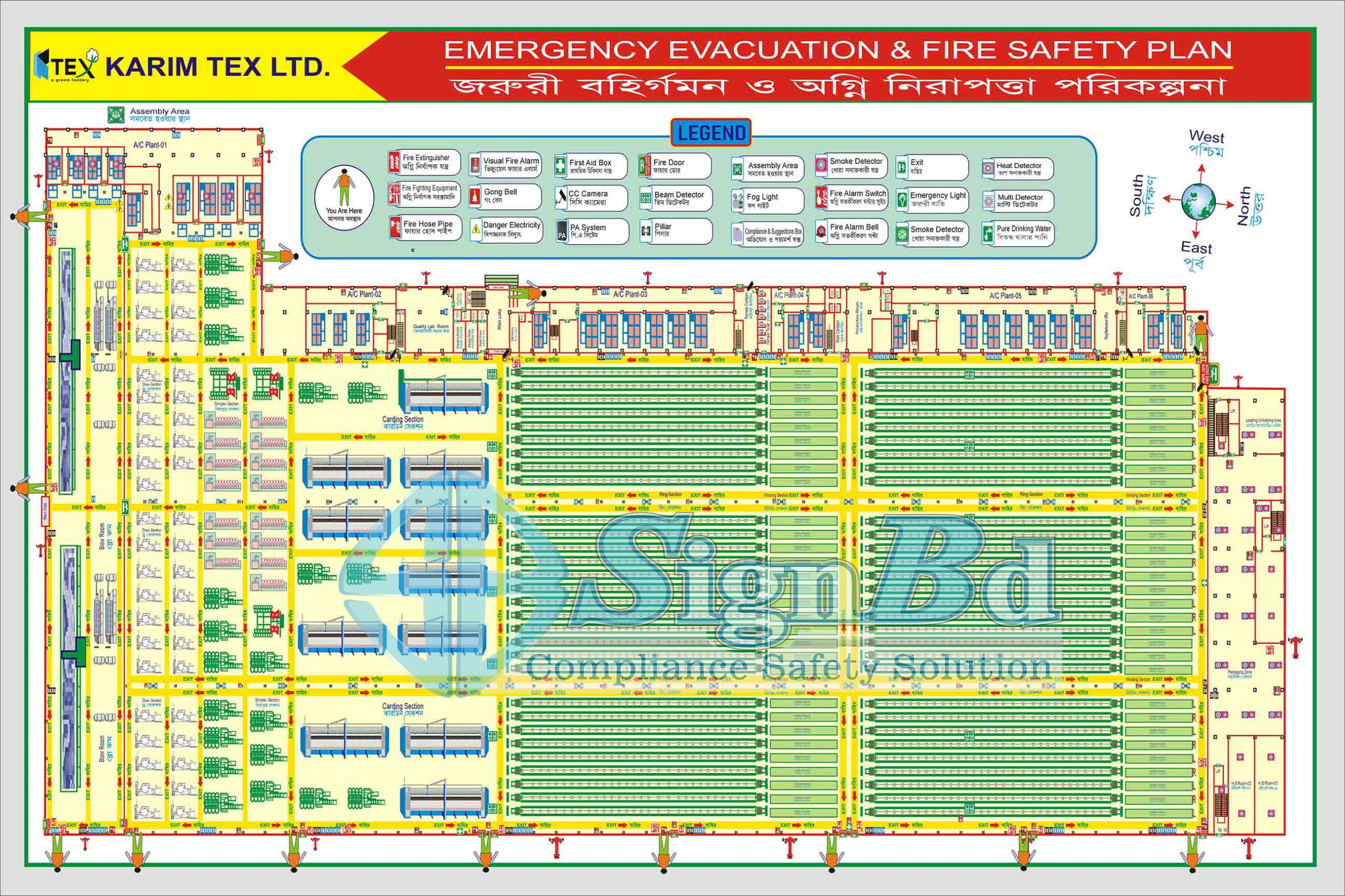

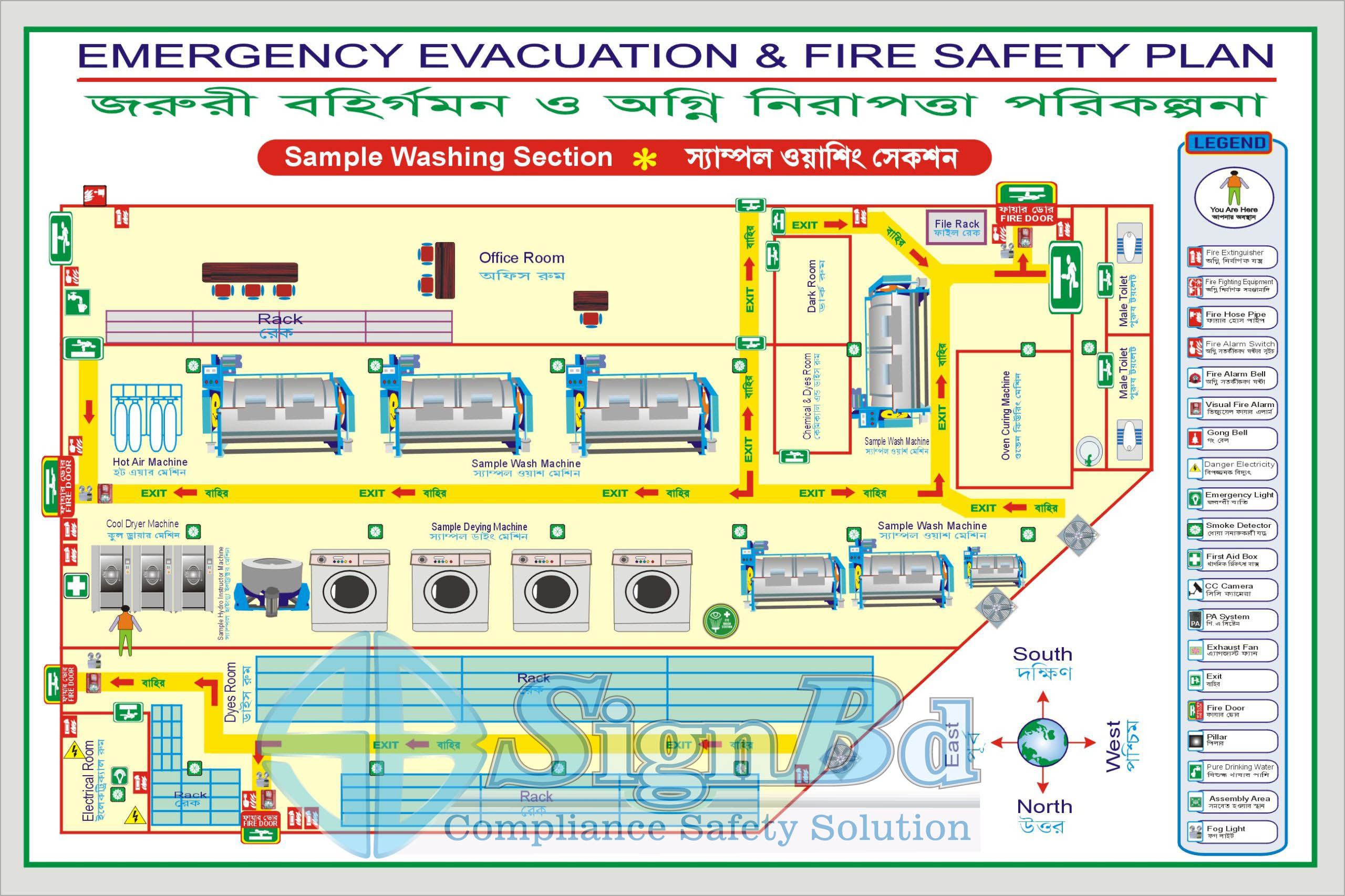

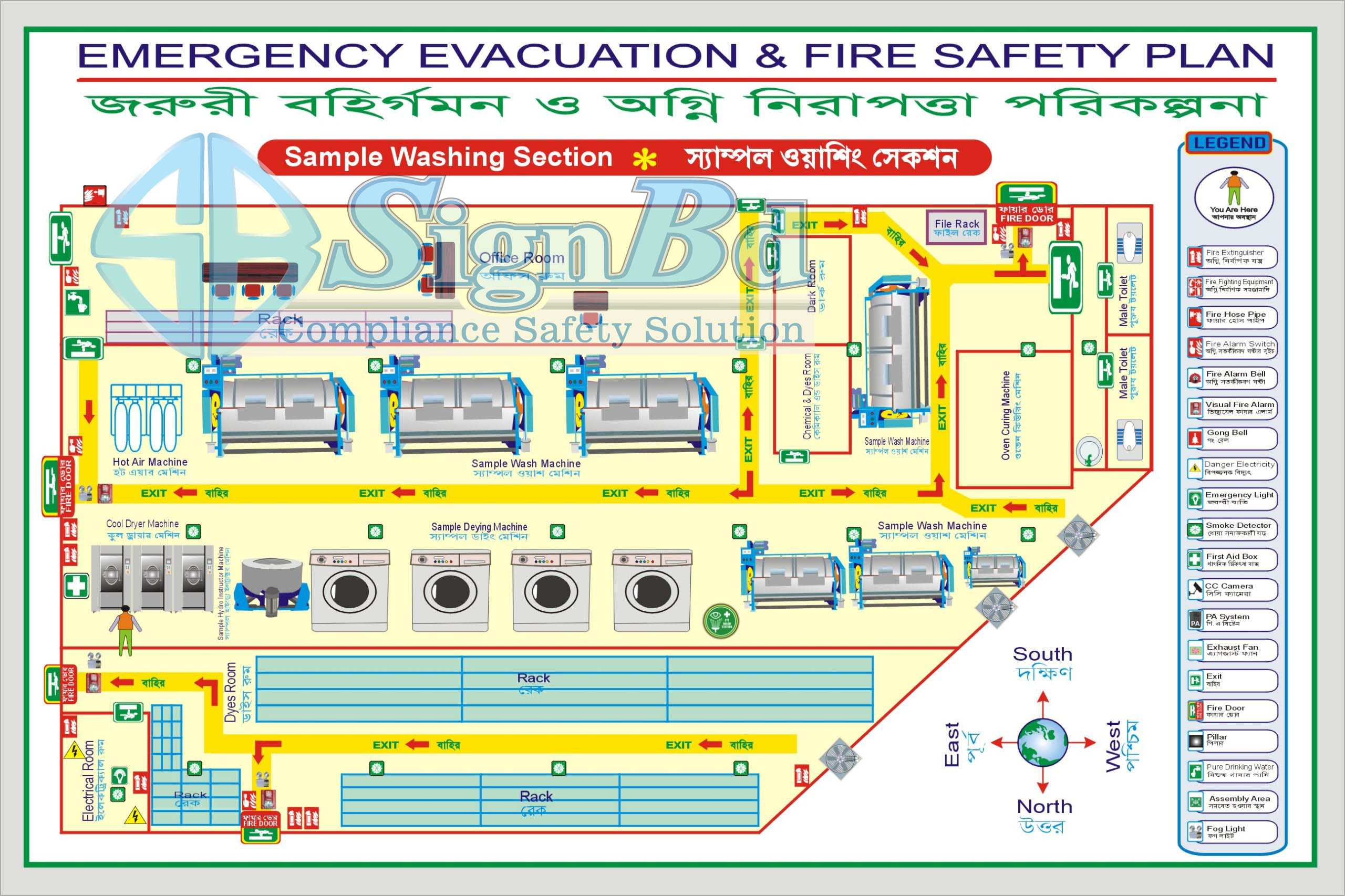

Your Custom Evacuation Floor Plan Design

The Essential Guide to Fire Safety Evacuation Floor Plans

Ensuring the safety of employees in factories, industries, and companies worldwide hinges on having a meticulously designed fire safety evacuation floor plan. This article delves into the critical nature of these plans, particularly in compliance with US and European standards, and emphasizes their role in safeguarding worker and personnel safety.

Gate in Touch:

Copyright © 2006 | Powered by signbd